Gray Cement

Cement is a hydraulic binder which hardens independently when mixed with water and remains solid in air as well as in water. The essential raw materials for the cement production are lime stone, clay and sand.

The most common cement is the so-called gray cement, which is called Portland cement in its purest form. The name was invented by Joseph Aspdin in his patent in 1824. It refers to the lime stone (Portland stone) from the Isle of Portland, a peninsula at the English Channel. Gray cement is most commonly used for producing mortar and concrete and is one of the most important binders for building materials worldwide. Depending on the production, Portland cement may be gray or white.

It’s the mixture

Gray cement meets different applications. In view of ecological and economic aspects, nowadays, Portland cement components are increasingly substituted by e.g. blast-furnace slags, puzzolana, fly ashes or lime stone powders. They influence the parameters of the cement e.g. workability, strength development and durability. Thus, the cement can be optimally tailored to the requirements on the construction site. And, there is more to it than that: Carbon dioxide emissions are reduced, too.

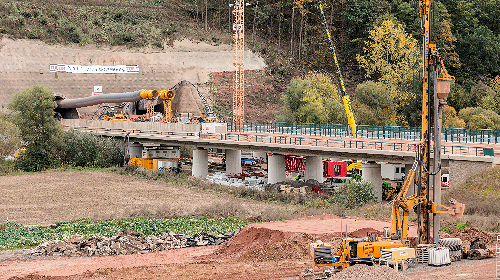

Dyckerhoff cement is firmly established in numerous constructions: large and famous, small and neat, just next door and everywhere in the world. In addition to standard cements, there are numerous specialties such as premium cements and products for infrastructure construction, geotechnical engineering and drilling.

The cement is either delivered in bulk (pickup and dispatch in silo trucks up to the customer) or in 25 kg bags (3 layers: 2 x high-quality paper layers + 1 x LDPE foil).